Indian Oil’s 2G Ethanol Plant at Panipat Refinery to bring multiple benefits to the nation

October 20, 2022

By Japan K Pathak, New Delhi/Panipat: Petrol that you purchase from petrol pumps for your vehicle has 10 per cent portion of Ethanol mixed in it. This Ethanol is domestically produced and therefore the import bill on that much of petrol is saved for the country. The Government of India has plans to increase the proportion of Ethanol in petrol to 20 per cent by 2025. It will save 20 percent import bill on import of crude oil. While country is gearing up to achieve this target, it is also adopting some path breaking measures. Conventionally Ethanol is made out of surplus sugarcane and rice stocks. However the 2G plant in Panipat Refinery in Haryana will produce Ethanol using rice straw, a substance which is known for its menacing effect on environment and air in Delhi and surrounding areas when it is burnt by farmers in open field. The success of this plant will result into multiple benefits. While stubble burning issue in three districts of Haryana will reduce significantly and help environment, the farmers will have added income from the agricultural waste. Employment generation and addition to economic activities shall be other advantages. Country’s march towards achieving target of 20 per cent ethanol blending will go further boost, that too with diverse source material as input. The spirit of Atmanirbhar Bharat will also have further push as the plant is indigenously developed.

Panipat Refinery

Commissioned in October 1998, Panipat Refinery is Indian Oil is 7th and the technically most advanced public sector refinery complex of India. Set up in the outskirts of the historic city of Panipat, The Refinery meets the demand of petroleum products not only in Haryana, but in the entire North-Western region, including Punjab, J&K, Himachal Pradesh, Chandigarh, Uttarakhand and parts of Rajasthan, Uttar Pradesh and Delhi. With a view to meet the growing demand of petroleum products, especially in the Northern region of India, the capacity of Panipat Refinery was expanded to 12 MMTPA in 2005 and again augmented to 15 MMTPA in December, 2010. The modern installation was further enhanced with the setting up of a world class petrochemicals complex. Further, to match the potential demand, a robust augmentation upto 25 MMTPA is already under way.

2G ethanol

One of a kind, first in Asia, the 2G ethanol plant at Panipat, based on state-of-the-art indigenous technology, will produce 3 Crore liters of Ethanol annually with rice straw – based lignocellulosic biomass as the feed, that will blend with petrol thereby offering to be a game-changer with respect to the present scenario.

Technology at Panipat Refinery

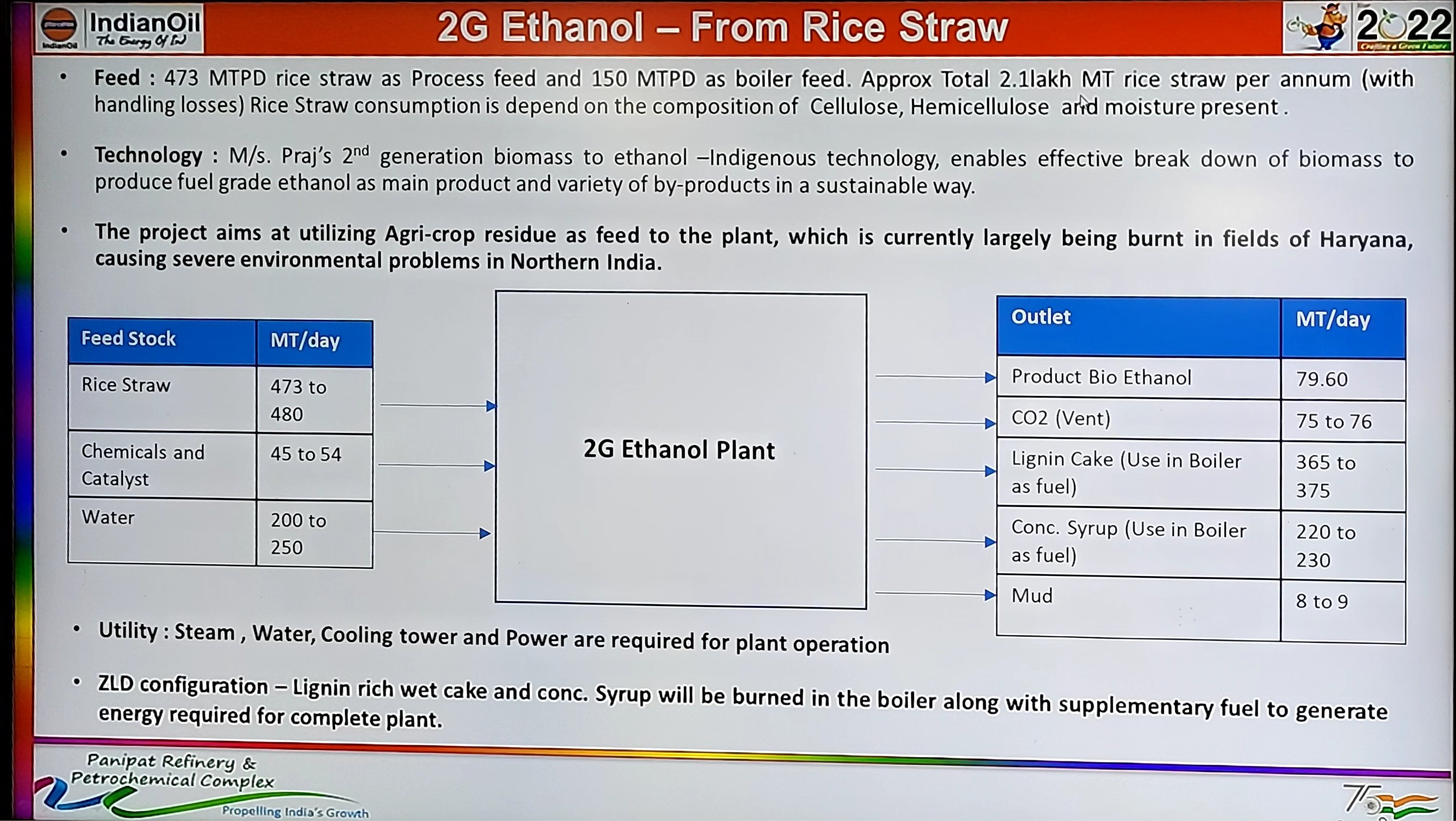

Based on “enfinity” technology the plant will utilize over 2 Lakh MT of rice straw annually as feedstock & secondary fuel (for boiler) to produce 3 Crore liters of Ethanol. The Ethanol will be blended in petrol to meet the Govt. of India (GoI) target of 20% Ethanol blending in Motor Spirit (petrol) and o er other benefits. The plant consists of Bio mass preparation section, main process plant, enzymatic hydrolysis, co-fermentation, distillation, degasifying column, split analyzer column, rectifier cum exhaust column, residue handling section and evaporators.

Envisioned and designed to revive rural society by o ering solution to crop residue burning, creating jobs and benefitting farmers by increasing their income; the 2G Ethanol project will utilise over 2 Lakh MT of rice straw annually, which will be collected from over 89,000 farmers in the vicinity of project site. The collection of rice straw from farmers will help increase their income directly. In addition, the project will create agricultural jobs through sourcing of rice straw. It is envisaged that ample emplyoment opportunities will be created for sourcing of rice straw annually. Rice straw will be collected from radius of 60 Kms and de-centralized collection depots will be created for collection.

In line with the vision of Shri Narendra Modi, Hon’ble Prime Minister of India, who has laid out India’s commitments towards climate action at CoP26 Summit in his ‘Panchamrit statement’ as five-point action agenda, this project is a big leap ahead.

To raise the non-fossil fuel-based energy capacity of the country to 500 GW by 2030. By 2030, 50% of the country’s energy requirements would be met using renewable energy sources.

The country will reduce the total projected carbon emission by one billion tones between now and the year 2030.

The carbon intensity of the economy would be reduced to less than 45% by 2030. Country would become carbon neutral and achieve net zero emissions by the year 2070.

Size and output of 2G Ethanol Plant at Panipat Refinery

Capacity – 100 Kilo Litre per Day Project Cost- 909 Crore

Ethanol Purity – 99.6%

Feed–Rice straw based lingo- Cellulosic

- The 2G ethanol plant at Panipat, will produce 3 Crore liters of ethanol annually that will blend with gasoline thereby saving crude oil imports. The economy will also benefit by tax revenue and GST income on ethanol. The project will revive rural society by creating jobs and benefitting farmers by increasing their income. The production of 2G ethanol will save GHG emission, thereby protecting our environment from pollution of crop burning.

Environmental benefits

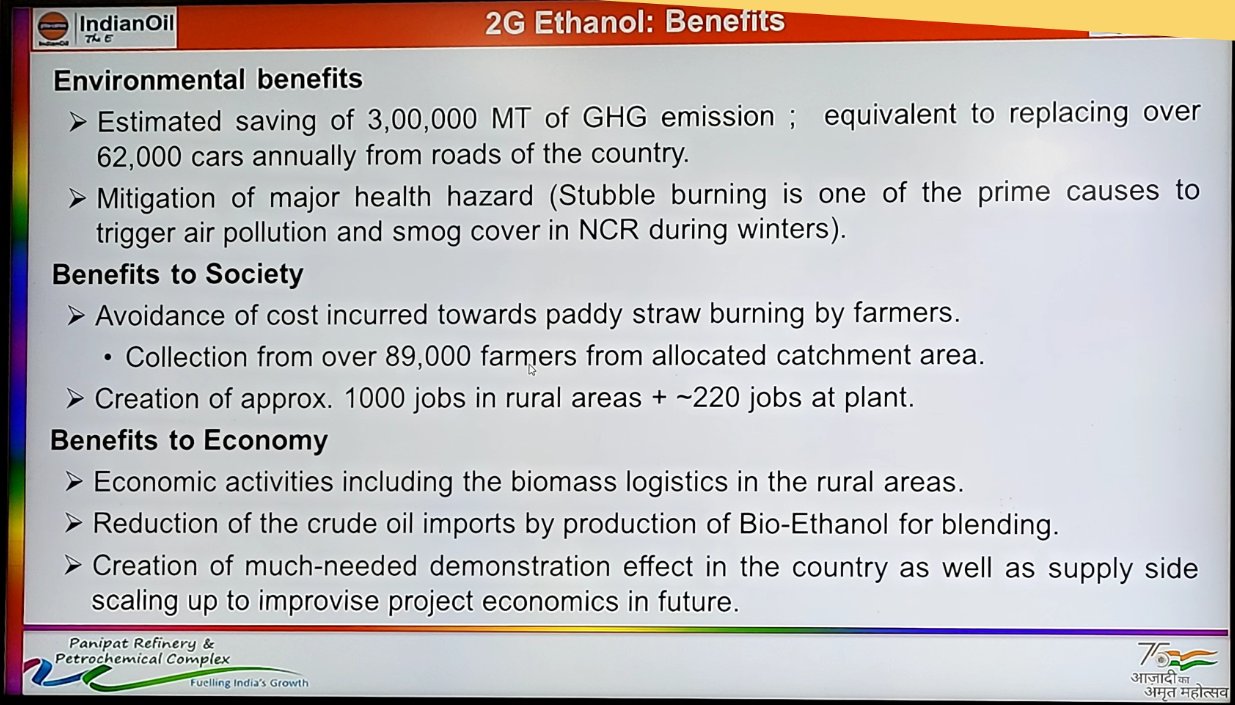

- This project will benefit environment by stopping rice straw burning and help reduce green-house emission of ethanol blending into gasoline. It will save 3,00,000 MT of GHG emission. This is equivalent to replacing over 62,000 cars annually from roads of the country.

- Additionally, burning of agricultural biomass residue, or Crop Residue Burning (CRB) has been identified as a major health hazard.

- The main causes of crop residue burning are two-fold. Firstly, there is a very short window of time between harvesting of paddy and cultivation of wheat, at the end of the Kharif season. Paddy, or rice, is a water-intensive crop. Secondly, the large units of harvesters leave 6-10 cm of paddy stalk on the field.

- The removal of the paddy stalk that remains on the field is a labor-intensive process. With insufficient labour and the time window for preparing the field for wheat cultivation being rarely used agricultural implements, or burn the residue right on the field. limited, the options that the farmer has is to either invest in expensive and Of the two, the latter is both cheaper and requires less effort.

Benefits to Society

- -Revive rural economy by creating jobs & additional income to farmers.

- -This project will require over 2 Lakh MT of rice straw annually, which will be collected from over 89,000 farmers in the vicinity of project Collection of rice straw from farmers will help increase their income directly.

- -Creation of over 1500 jobs in rural areas will help local villagers.

Panipat Refinery’s Benefits to Economy

- -Reduced air pollution due to prevention of stubble burning in paddy

- -Incremental income to farmers by creating an end-use for the agri-crop

- -Biomass logistics will create additional economic activity in the rural

- -Employment Generation: The 2G Ethanol Project will provide direct employment to people in plant operation. Further indirect employment will be generated in the supply chain for rice straw cutting, handling,

- -Atmanirbhar Bharat: The project involves first commercial plant based on the Indigenous technology of M/s Praj Industries Limited. No other proven technologies are available in Asia as on date for 2G Ethanol production.

- -Reduction of the crude oil imports by production of Bio Ethanol

While production of ethanol is not new, the 2G plant is path breaking because the source material is something which was not tried before. While rest of the process of making ethanol out of sugar remains same, the process of making sugar from rice straw is something new and that’s the difference here. One of the challenges is to store rice straw stock which comes out from the field once in the year, while the ethanol plant has to run throughout the year. All arrangements in this regard have been done for 2G plant. It is learnt that the government is also in process to make ethanol from Bamboo in North East and generate gas from agricultural waste in Punjab. While the Centre is ready to do all, the support of the State government is crucial in this endeavor. Haryana government has done all possible to ensure success of Panipat 2G ethanol plant and the wider cause and mission involved in it for the good of the nation.

Related Stories

Recent Stories

- Police nab 3 from Vatva with 23 robber mobile phones

- Rajkot District Election Officer gives clean chit to Rupala over his Roti-Beti remarks

- Tharad Congress leader DD Rajput joins BJP with supporters

- Bikers tease lions in Gir National Park; Video goes viral

- Public holiday on 7th May declared in Gujarat

- Rupala to file nomination for Lok Sabha polls on April 16th

- BJP to hold Modi Parivar Sabha public meetings during 8-16 April